Sovol SV06 upgrades

In this post, I have grouped all the improvements I made to my Sovol. Some of them are original designs by me, others are remixes, and the remaining are from other designers. Check out the links.

- Hillsoftware alternative firmware (more details on my previous post about the SV06).

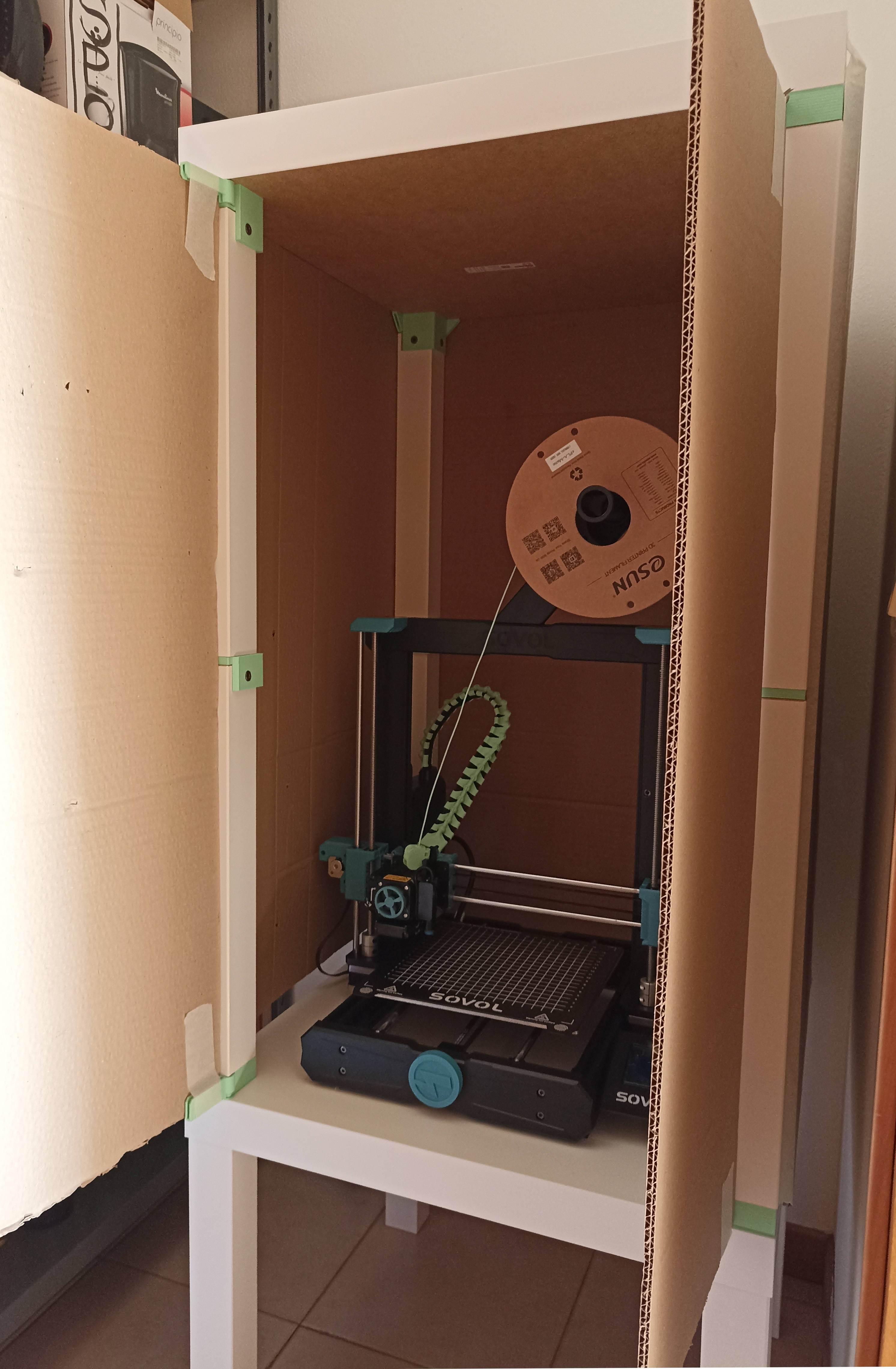

- My version of the famous IKEA Lack enclosure, adapted to preserve the spool inside the housing.

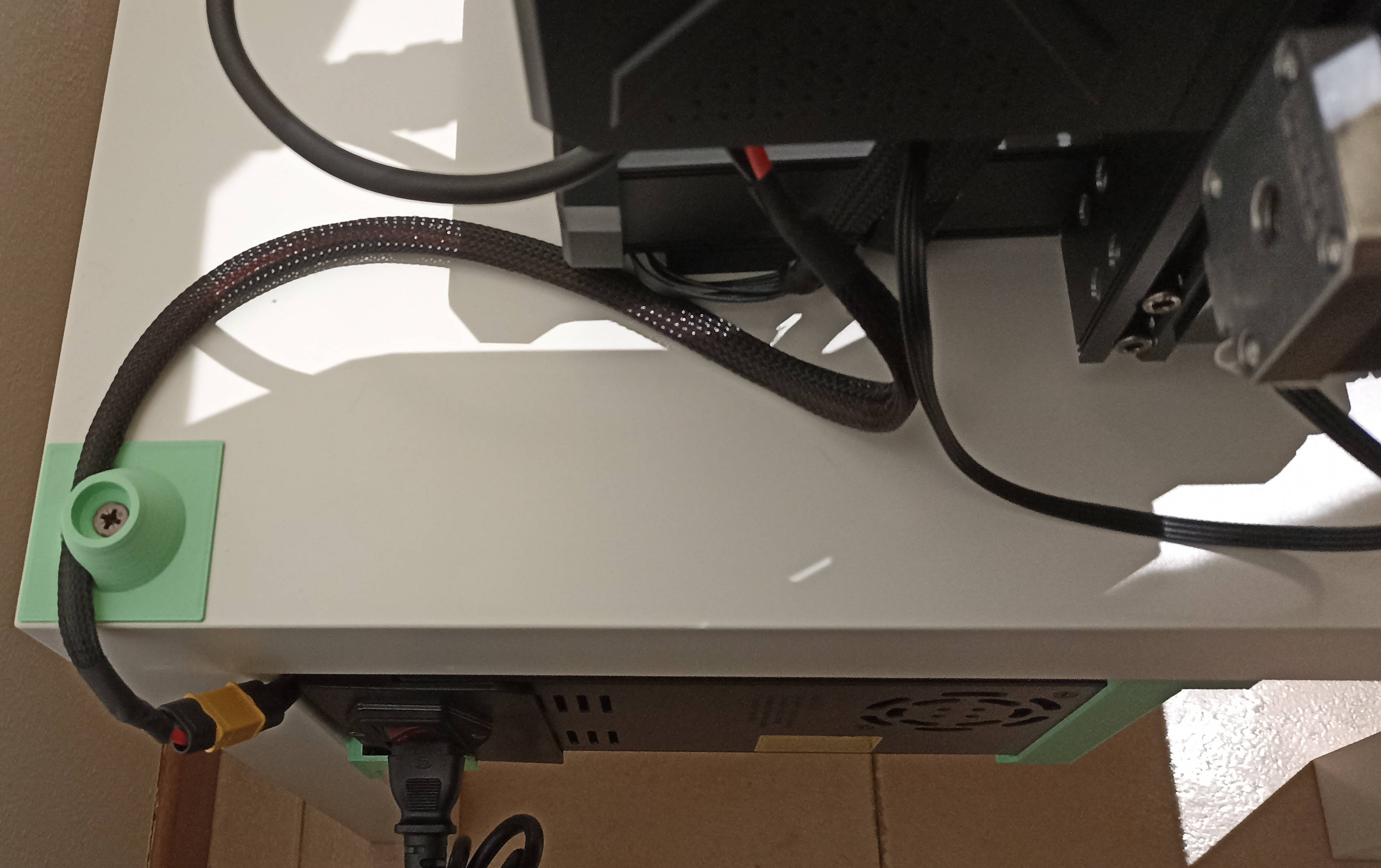

- PSU holder to mount the stock PSU outside of the enclosure, ensuring proper cooling.

- The custom end part of the slicer code to exclude "presenting the bed" at the end of each print.

This was necessary because the bed would have hit the enclosure's doors.

Update: Now I have a better positioning that doesn't require it because I have made a bed cable holder that lets me position the printer in the center of the enclosure (more on that later in this post). I leave this bullet point anyway for reference. - Slicer bed texture for coolness during preparation. (⌐■_■)

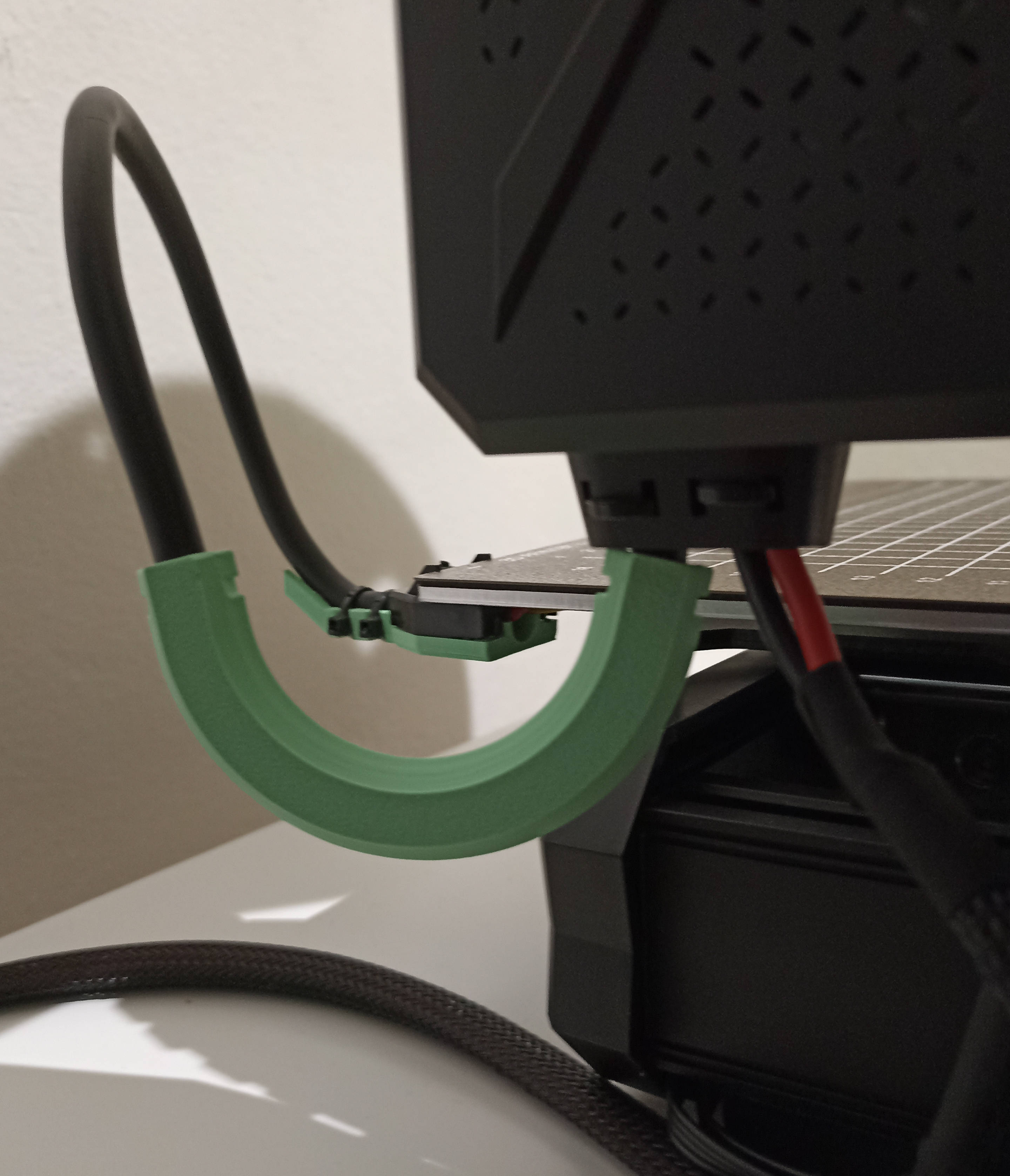

- Strain relief for bed cable, preventing the classic problem that affected all my headphones during my teenage years.

- Bed cable holder to give the cable an upward twist and let me position the printer further inside the enclosure without hitting the back panel nor the doors.

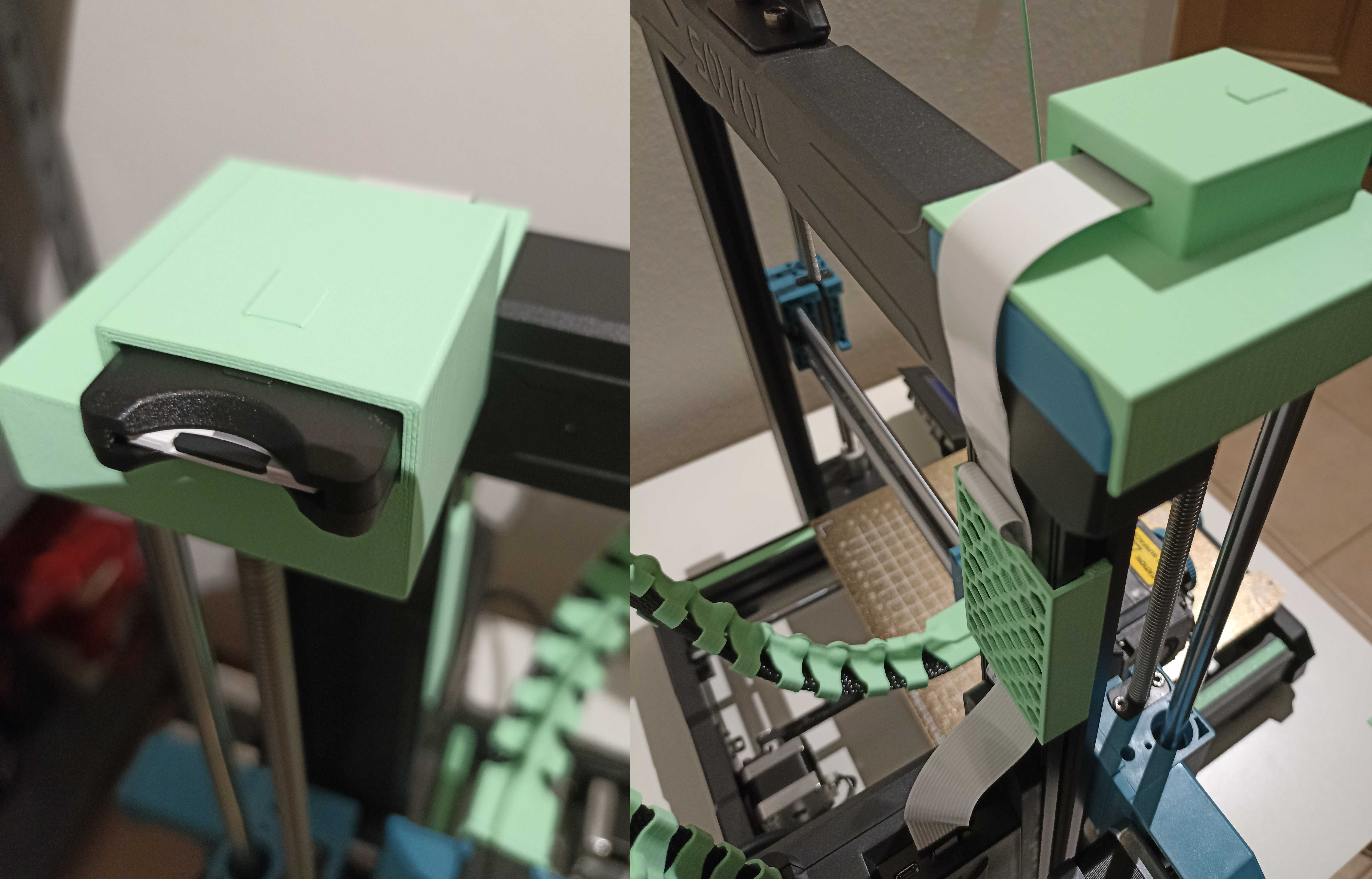

- Spine for extruder cable to keep it high and prevent interfering with the print (like this).

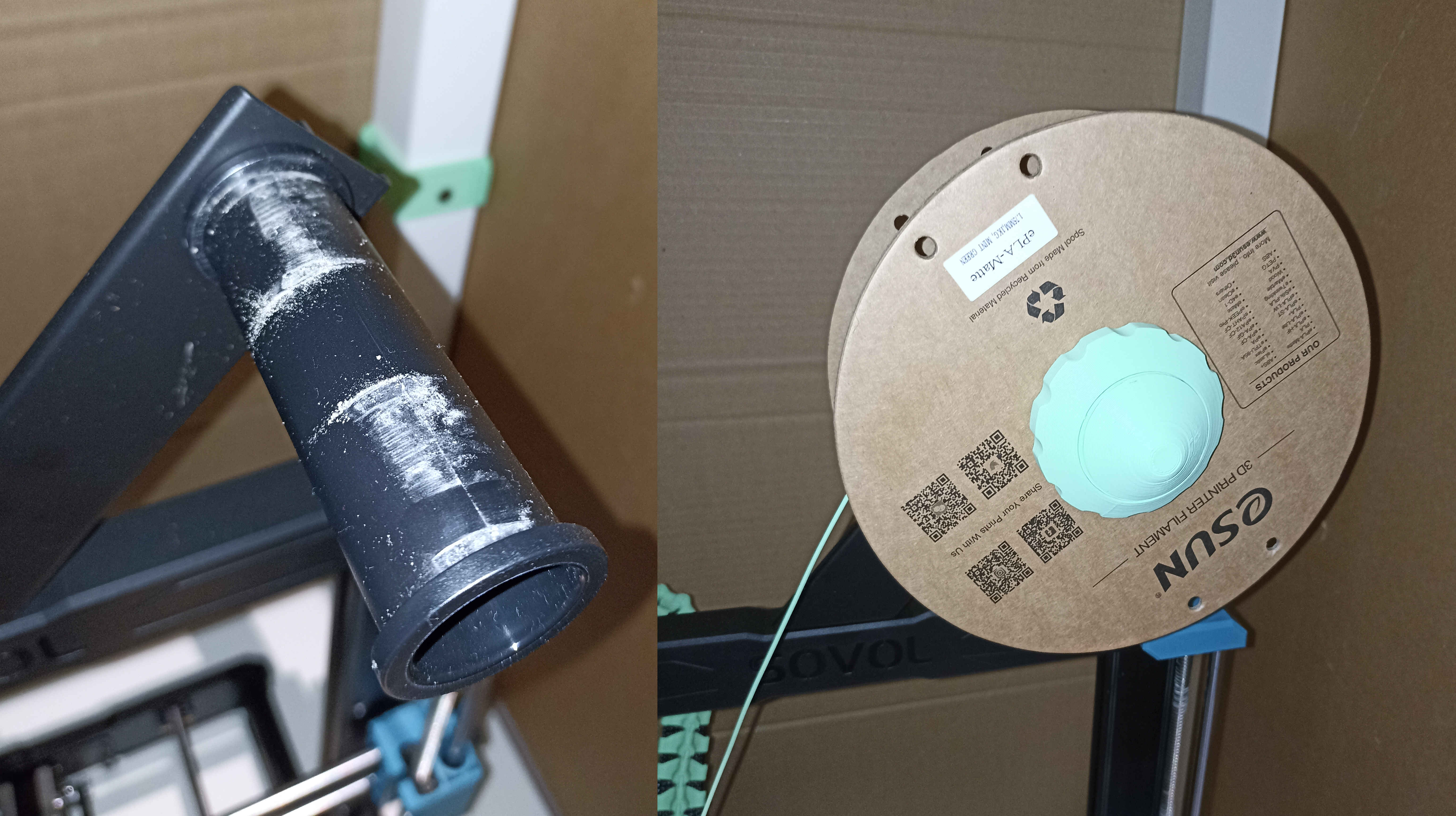

- Extrusion covers for easier cleaning.

- Spool shaft to prevent cardboard dust generated by friction between the stock one and the cardboard spools.

- Filament dust cleaner. Simple and nice print-in-place addon. I used Geomag magnets.

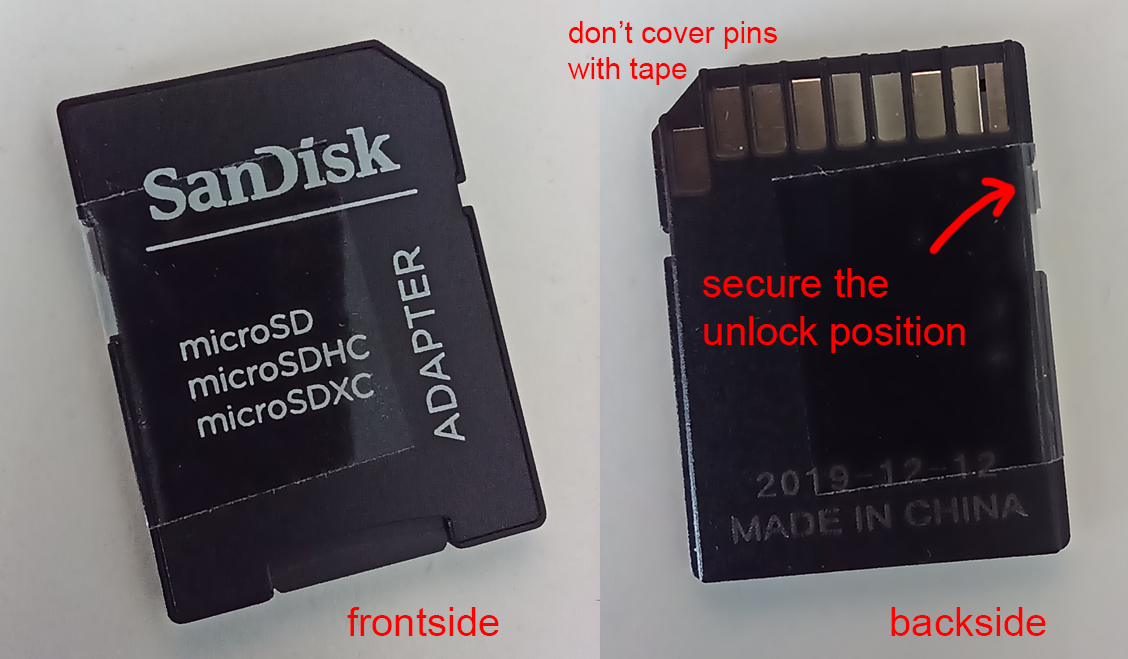

- Full-size SD card extension.

MicroSDs are not designed to be inserted and removed a lot of times (this is why high-end cameras still use full-size SD cards).

Plus I found very inconvenient the microSD slot placement paired with an enclosure.

AUFMERKSAMKEIT: for some reason, the LOCK pin on the adapter seems to move when I insert the full-size SD inside the extender causing the print to stop after some layers. I fixed it by putting tape on the adapter as shown in the photo below. - Tool organizer. Best way to keep all the printed-related tools near the workspace.

- Custom G-code for pause mid-printing. Sometimes you need to program a pause to insert nuts, weights, or other things inside a 3D printed shell (see my begleri for example). This is the code added in Prusaslicer>Printer settings>Custom G-code:

- Extra: Wire cutter fix. Prevent the spring of the stock Sovol wire cutter from popping out of its placement.

;this is a comment

G91 ;switch to relative positioning

;G1 Z2 F1000 ;default lift nozzle

G1 Z20 F1000 ;custom lift nozzle because I commented G27 line (relative)

G90 ;switch to absolute positioning

;G27 P2 ;park extruder to NOZZLE_PARK_POINT coordinates defined inside firmware as follows

;NOZZLE_PARK_POINT = (X_MIN_POS(=-3) + 10), (Y_MAX_POS(=220) - 10), 20

;but P2 make always lift extruder by Z_PARK amount(=20) without exceed Z_MAX_POS(=250)

;this is why I had to manually set custom lift nozzle

G1 X7 Y160 ;custom XY coordinates because I commented G27 line (absolute)

G1 X7 Y160 E0 ; custom XY coordinates to stick bed out, stop printing

M300 S440 P200 ; beep

M300 S660 P250 ; beep

M300 S880 P300 ; beep

M0 Click to continue... ; stop and wait user input to proceed

M105 ; return to current temperature

Note to my future self: keep this list updated when changes happen.